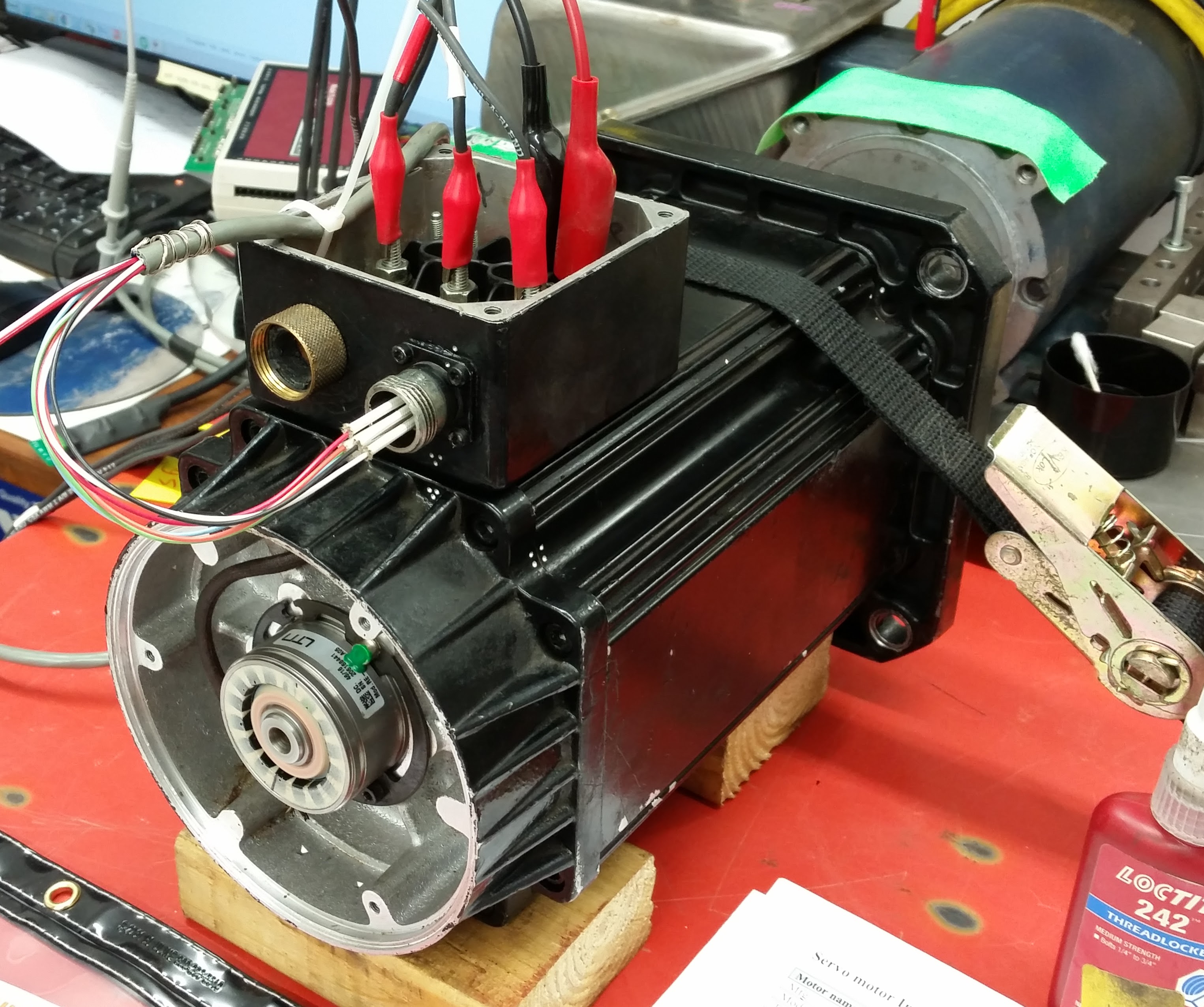

Servo Motor Repair

At Acme Armature Works, (Acme Servo) we are striving to be the best in Servo Motor repair. We are experienced technicians who can service the most complex motors being used by today’s manufacturers. We specialize in fast, accurate repair, rewind and re-manufacture of all brands of new or used servo motors. During our repair process, every encoder or all feedback devices are checked for proper signals and alignment. All motors are fully disassembled and documented to check bearing journals, housings, shafts, keyways, and flanges are all checked for proper tolerances. After re-manufacture Motors are run-in temperature, noise, balance/vibration, and response are monitored and permanently recorded. Every motor is dynamically tested to ensure a successful repair was conducted and then returned to the customer looking like new. Contact us for more information.

Quick Turnaround Times

Typical repair time on a normal servo motor repair is 5-7 days. For rush repairs, please allow 1-3 days. We also offer an extreme Emergency Service, Upon receiving a purchase order we will stay on your project night and day around the clock until the job is finished. We are ready no matter what the time! Learn more.

Value Added Servo Motor Services

- Full Modern Machine Shop Capabilities

- Brake Repair and coil rewinding + potting

- Winding Encapsulation

- Re-magnetizing

- In-House Balancing Department: Balance rotor and rotating parts to ISO G1.0 tolerance

- Mechanical upgrades for common failures

- Motor sealing for wet environments

Servo/Spindle Testing

- Closed Loop Test Run

- Encoder

- Resolver

- Tachometer

- Hall Sensor

- Serial Encoders

- Special Odd or OEM Feedback Devices

- Heidenhain OEM ATS adjusting and testing

- Sick Stegmann OEM programming tool

Servo Motor Retrofits

Replace obsolete motors with new stock motors made to fit your existing application and mounting. New technology offers better performance and less maintenance!