By Jeff Pederson – Pedal Down Promotions

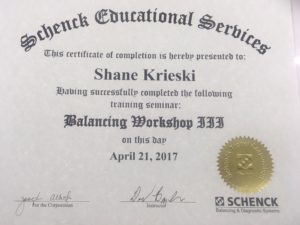

In an effort to expand their capabilities to address various unique and challenging rotor balancing issues, Acme Armature Works Inc. Owner Chad Bahrs and Service Technician Shane Krieski completed a Schenck Educational Services Rotor Balancing Workshop III training seminar in Chicago, Ill. on April 21, 2017.

The day-long workshop was presented in an open-forum format, during which participants could review basic electric motor balancing principles, improve rotor balancing skills and address specific application challenges.

“The class was an extension of the basic rotor balancing class,” Bahrs said. “It was more advanced and covered quite a bit of things that are not taught in the basic class. It began with an introductory slide show and an overview of different rotor configurations. From there, it got into a lot of specific questions that people had about their specific balancing machines and difficult situations they’ve encountered.”

According to Bahrs, the seminar placed a heavy emphasis on specialized cases.

“The bulk of the instruction was on how to address different and unique rotor configurations in one or two planes to improve unbalance reduction ratio and plane separation,” Bahrs said. “We learned a lot of different ways to address specialty balancing and out-of-the-ordinary situations, which made the course very useful for us because these are things that we deal with in our shop on occasion.”

“The bulk of the instruction was on how to address different and unique rotor configurations in one or two planes to improve unbalance reduction ratio and plane separation,” Bahrs said. “We learned a lot of different ways to address specialty balancing and out-of-the-ordinary situations, which made the course very useful for us because these are things that we deal with in our shop on occasion.”

The workshop gave Bahrs a valuable opportunity to gain additional knowledge based on the experiences of other repair technicians in the electric motor repair field.

“It was an interesting experience because we were able to learn a lot from everyone else that was in the class,” Bahrs said. “We got to learn about issues other people are having and we got to see how other people in our field do things. It was very hands-on and directed by the questions of the class participants, which made it a bit different than some of the other training workshops I’ve attended over the years.”

Bahrs is eager to pass along the concepts learned during the workshop to better assist Acme’s loyal and expanding customer base.

“These training experiences are important because they help us to stay sharp and responsive to the needs of our customers

“These training experiences are important because they help us to stay sharp and responsive to the needs of our customers,” Bahrs said. “We are always looking for different ways to improve the repair services we offer and this seminar helped a great deal to hone our rotor balancing capabilities.”

For more information or to request service with Acme Armature Works Inc., email [email protected], call the 24-hour service line at 920-452-3389 or visit www.acmearmature.com.